Some few months ago, while driving on a highway, from Abuja to Lagos, Nigeria, I experienced something terribly astonishing; when I tried accelerating the engine of my M45 Infiniti 2003 seden V8.

- I suddenly lost throttle power, and couldn’t ascend one of the Benin-Ore expressway.

- I tried all I could to ascend that hill, to no avail.

- Pulled over from the express way, turned off the engine, waited a few minutes, then started the engine once more.

- Shifted all the gears to ascertain if the problem was coming from the throttle body assembly, or from the transmission system.

- There are times the transmission system would flare, from gears 1-2, before it finally engages to the next gear.

- At other times, nothing happens, and the transmission system feels as if it’s in neutral.

SO WHAT ACTUALLY WAS THE PROBLEM?

Here’s what I did, or started doing, and which I encourage any car owner, or mechanic should embibe.

- When in the middle of nowhere, and such potential mechanical issues pops up, do not PANIC! Be calm.

- Check the transmission system fluid FIRST, before doing any other thing. If the transmission fluid looks dark, and dirty, or smelling burnt, replace the fluid, and test the vehicle.

- Get a code reader, and retrieve any trouble codes that might be logged in the car’s ECU (computer).

You could get one of these code readers for cheap, on eBay, or Amazon. They come handy, and would save you alot of heartaches, and frauds from some mechanics.

The trouble codes can also be retrieved from any of your trusted auto parts store for some fee.

Getting codes retrieved narrows down the faults, and saves you money and time from throwing money at parts, just to solve a problem.

3. Here were the retrieved trouble codes I got when I scanned the engine/transmission system:

P1772 low coast brake solenoid; P0037 heater oxygen sensor B1S2; U1000; P1815

4. Recorded all these codes, including their freeze frame data. The freeze frame data helps you know exactly at what operating conditions, or parameters, the codes or problems occurred.

5. Cleared all the codes, inorder to see which ones would be left out or reappear. It’s neccessary to always clear error codes, after recording them down, before proceeding with diagnosis.

6. After clearing all the error codes, only the transmission system related codes were remaining: P1772, and P1815, which had narrowed down the possibilities of where the fault was coming from.

7. Did some more research on the codes, and realized, these were trouble codes, related to the low coast brake solenoid, and manual valve in the transmission system.

Always spend more time researching trouble codes, before jumping into conclusions, on where the problem might be coming from.

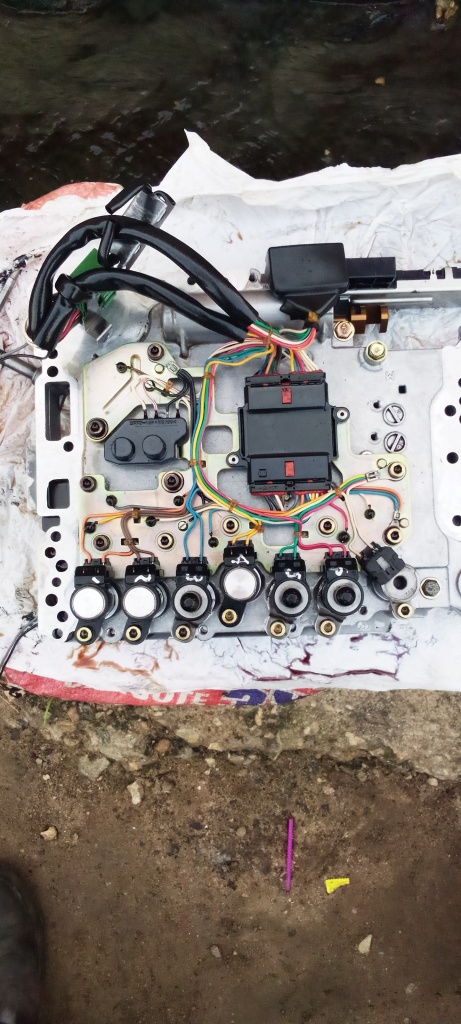

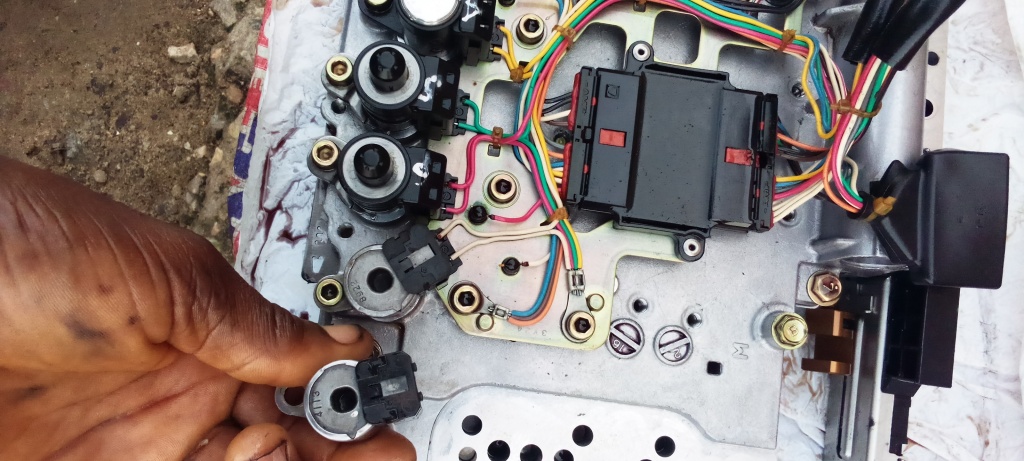

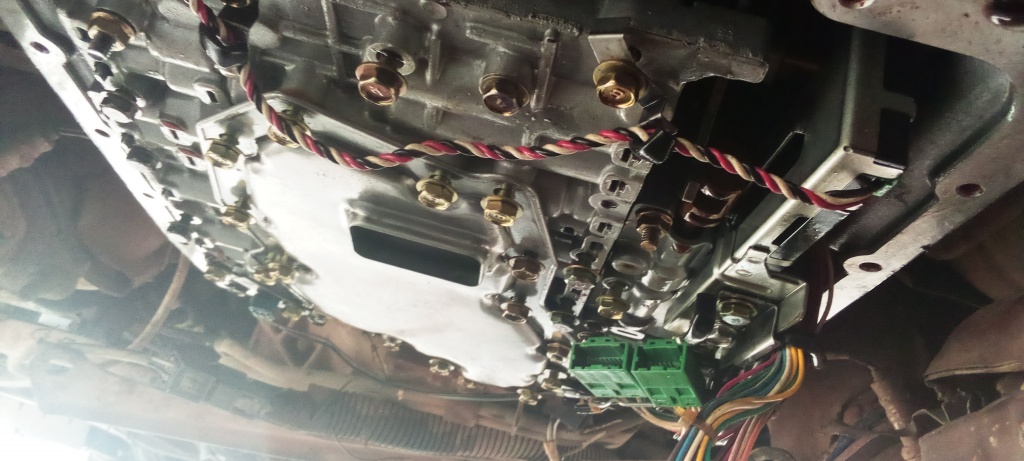

Solenoids numbered from 1-7 with the 7th been the faulty one

Some of these problems plaguing vehicle owners, may have been dealth with by technical service bulletins issued out by vehicle manufacturers to dealerships, available online, or elsewhere.

Luckily for me, my car had no known such issues with it’s transmission system, because of it’s external TCM (transmission system control module) mounted beside the car’s ECU.

In some modern Nissans and Infiniti vehicles that precedes my car(2004+), their transmission systems, have been known to be plagued with a gel like substance, as a result of radiator coolant leaking through the transmission system cooler lines in the transmission, and straight to the valve body of the transmission system. These has been the sole reasons why Nissan/Infiniti, with the RE5RO5A transmission system in Pathfinders, G35, Amada, Fx35/45, have been failing and keeps failing. They tend to corrode the terminals of the circuit boards on the TCMs, causing failures.

To fix such problems, means you got to replace the radiator assembly entirely, or get the transmission system an external oil cooler to prevent recontamination ( this helps in cooling down the transmission fluids, and finally replace the valve body, which does not come cheap.

8. From the research, I was able to identify which of the solenoids was failing, or bad.

Since my car’s TCM was externally placed, and not in the transmission system, like other Infiniti and Nissan vehicles that precedes my car, I was damm too sure, not fluids contamination, but was either of two causes:

a) the solenoid may be failing, or bad

b) the wiring harnesses on the solenoid itself, or on that circuit, had shorted out, or had an open circuit somewhere.

Those were the only two possibilities that could trigger those codes, and perhaps, a faulty TCM. I had already ruled that out, since I had checked all the wiring harnesses on the TCM harness connectors, for any signs of brittleness, discolorations, due to corrosions(from coolant contamination), and they all checked out clean.

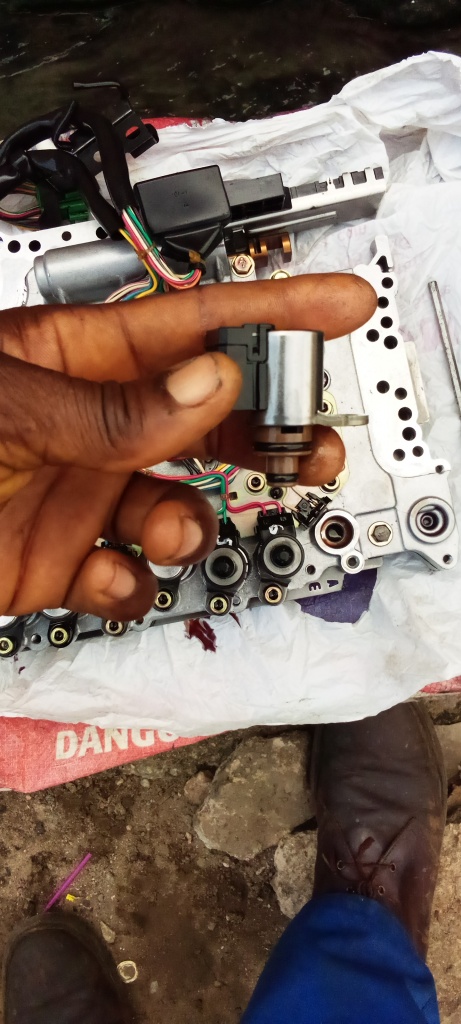

That’s the low coast brake solenoid that was failing.

solenoid removed and discarded

THE MAIN TASKS NOW(GETTING YOUR HANDS DIRTY)!

- Got the car on jack stands, and wedged it. We do all these, for safety purposes.

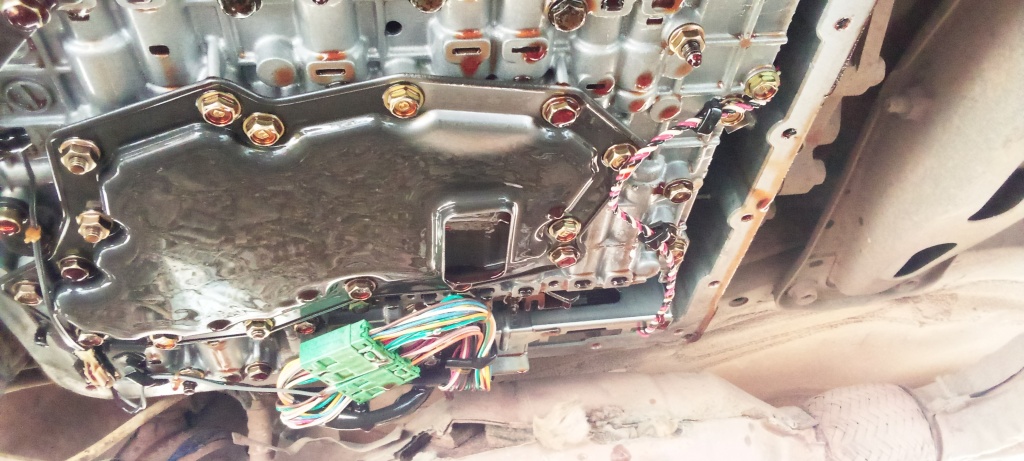

- Drained the transmission fluid, and removed the transmission pan. Always take note of the quantity of fluids drained, so you know how much quantity you got to refill in there. The transmission pan bolts were all sizes M10.

- Inspected the transmission system pan magnet, for presence of either aluminum burrs, or brown particles from the transmission. Surprisingly, nothing out of the blues was worrisome. The transmission fluid also looked pretty clean, and tan in colour.

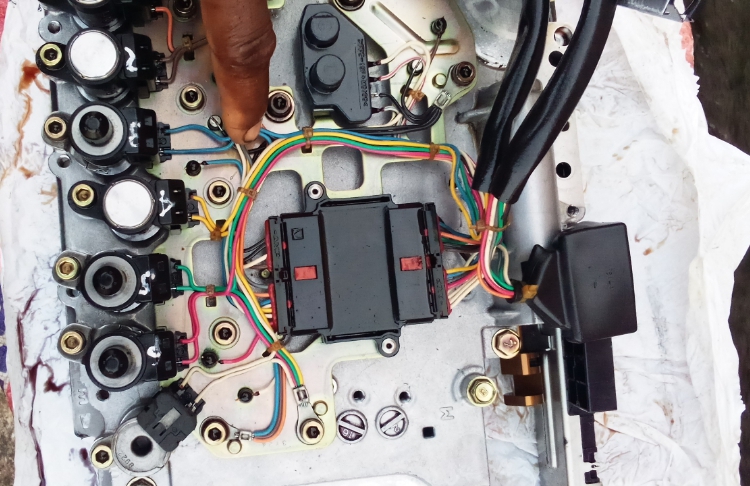

- On the RE5RO5A Nissan/Infiniti transmission systems, removing the valve body, you have to be very careful, not to mix the different sizes of M10 hex bolt heads, because they are of different lengths. Mixing them, would cause pressure loss and/or transmission engagement issues.

- What I did inorder not to get the various bolt sizes mixed up was to do a kind of like a 3D copy of how my valve body looks like, and the various points the bolts should go into before and after removing them. I had to colour code the bolts also. You can replicate same, if you’ve got challenging tasks as these, where you got lots of bolts to work with. I used cardboard paper to replicate that, it helped and quicken the job.

- Finally got the bolts on the valve body removed, with the ALIGNMENT BOLT, CLOSER TO THE TRANSMISSION PARK NEUTRAL SWITCH been the last to be removed. The alignment bolt, helps to support, and align the valve body, when removing or installing it on the transmission system. Without this bolt, the valve body would be difficult to align, leading to transmission problems, since other bolts won’t align and torque to exact specs.

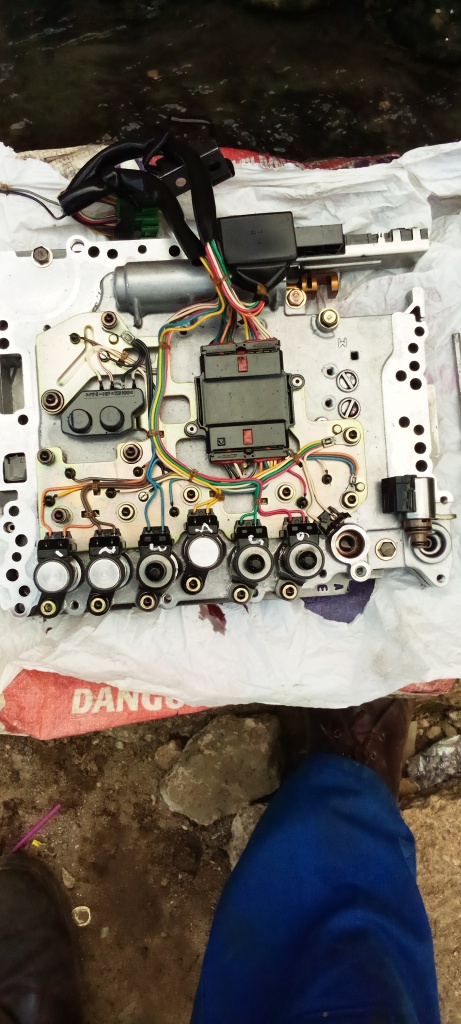

- After valve body bolts were removed, and the valve body placed on a flat surface, it was now time to IDENTIFY exactly which and where the solenoid was located, amidst the others on the valve body. This solenoid looks very different from the other ones. They just can not be interchanged when replacing them. The solenoid is the one on the extreme end by the right(#7).

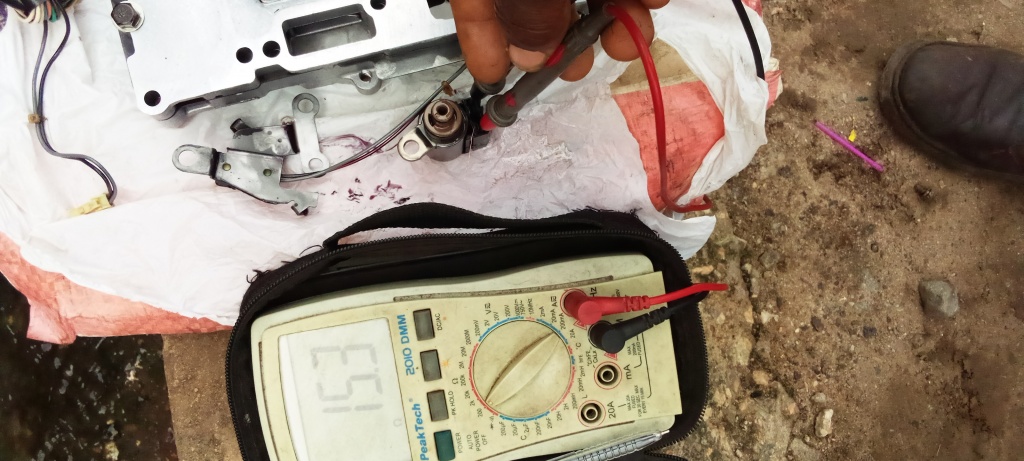

- Did a resistance and continuity tests on the low coast brake solenoid, and it’s wire harness circuits. Tests such as these, would help you figure out, if the problem is a wire harness one, a failing or failed transmission solenoid. Do not outrightly replace a solenoid, just because a scan tool retrieved trouble codes referencing such solenoids. Always carry out resistance, continuity, and even power/ground tests, to rule out a circuit failure problem.

- Knowing what specifications required for such tests, is paramount to solving this problem. Since my car’s transmission system, was a 2002-mid 2004, and with it’s TCM external, there were two designs for the low coast brake solenoid. One was for a resistance range of 10-15ohms, while the second design, was for resistance range of 20-40ohm. In my case, testing the resistance, it fell on the first only Infiniti design(10-15ohms). I got a reading of 15.2ohm, which was already outside the range specifications. This was where my problem lied. If I wasn’t proactive with the diagnosis, this would have called for an outright valve body or transmission system replacement.

- Knowing fully well that this was the problem, I ordered the same type of solenoid for replacement. Read the resistance on that one, and also tested it’s plunger protrusions, by applying 12V battery power to it for few seconds. Resistance reading was about 12.0ohm, within range.

- Torqued the replacement solenoid 5mm Allen bolt, and connected all the solenoid connector harnesses. Double check your connections at every assembly, before installation.

- Reconnected all the wire harnesses on the valve body FIRST, and aligned the alignment bolt, and the manual valve plunger on the neutral park switch.

- Inserted all bolts on the transmission pan, and hand tightened four bolts on the corners of the pan. This would assist in uniformly tightening or aligning the other bolts finally.

- Cleaned up the pan itself, washed all bolts, and applied silicone sealants on the it mildly. This would properly seal the pan gasket and prevent any fluids leaking.

- Tightened all the other bolts in a cross cross fashion, and allow the sealant to dry out before putting in the transmission fluid.

- Replaced the transmission fluid with the recommended fluid for my car(MATIC J), and nothing else. If you want to save your transmission system, always use recommended transmission fluids by your car’s manufacturer.

- Start the engine, allowed it to warm for few minutes, shifted all the gears, and re-guaged the transmission, and took the car for a ride.

- You won’t believe what happened. My car’s transmission system now selects like a charm, without the usual FLARE, and the LACK OF UPSHIFTS ON 4TH GEAR, that was the problem.

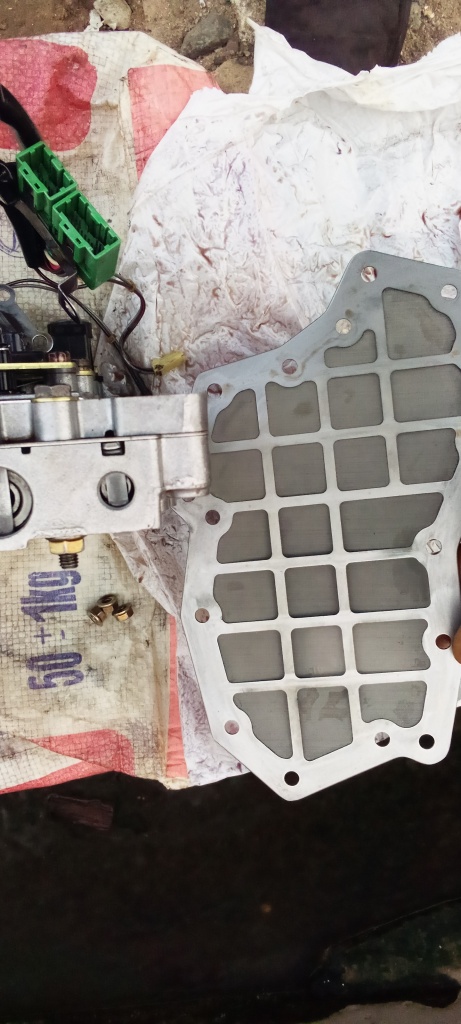

this is the outside view of the transmission filter

tbis is the rearward view of the filter screen. Notice it has wider openings with right pore sizes for filtration

Shows the other solenoids

In summary, some transmission system problems are not that complex, that would require a transmission replacement. With the right, and basic tools as a car enthusiast, or technician, diagnosing and fixing your transmission system, won’t be difficult, would be more cheaper than getting a new(used) one. The key to fixing these transmissions is researching the problem(or symptoms) FIRST, and narrowing it down to a suspect component, or circuit. It is pertinent to test all solenoids to ensure that they are all within the specified resistance ranges recommended by the manufacure before installation.

Disclaimer

I do not claim to be a transmission system specialist. That is not my specialty. This article tries to put you through how you can also solve transmission system problems like these one, by doing the simple things first, instead of spending money outrightly to replace a transmission, only if you’re mechanically inclined. I bear no responsibility, if you damage your car’s transmission system, by doing things, your own way. If you’re not mechanically inclined, please do not attempt to carry out this repair. Instead, high and pay a professional to help you out.